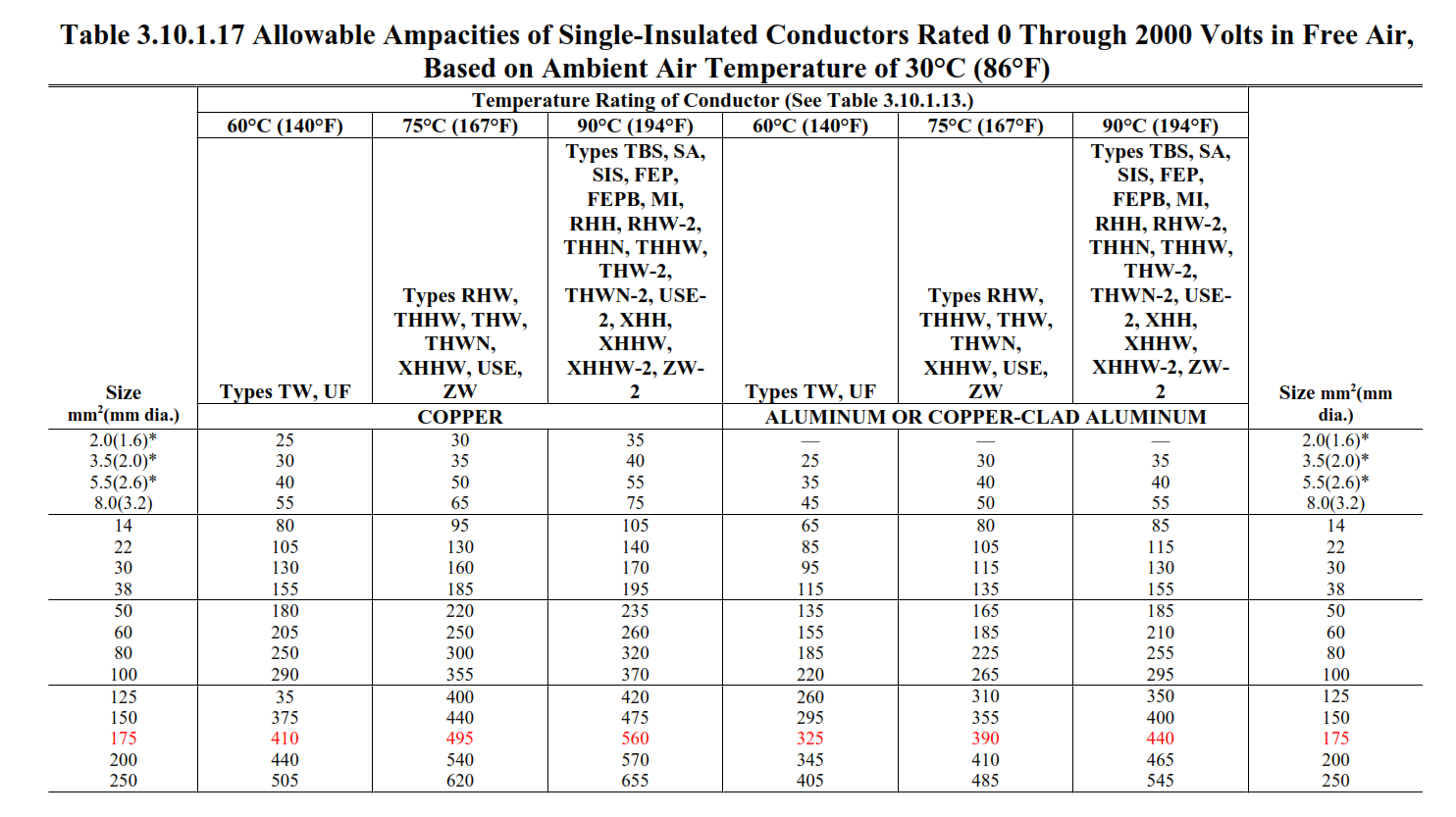

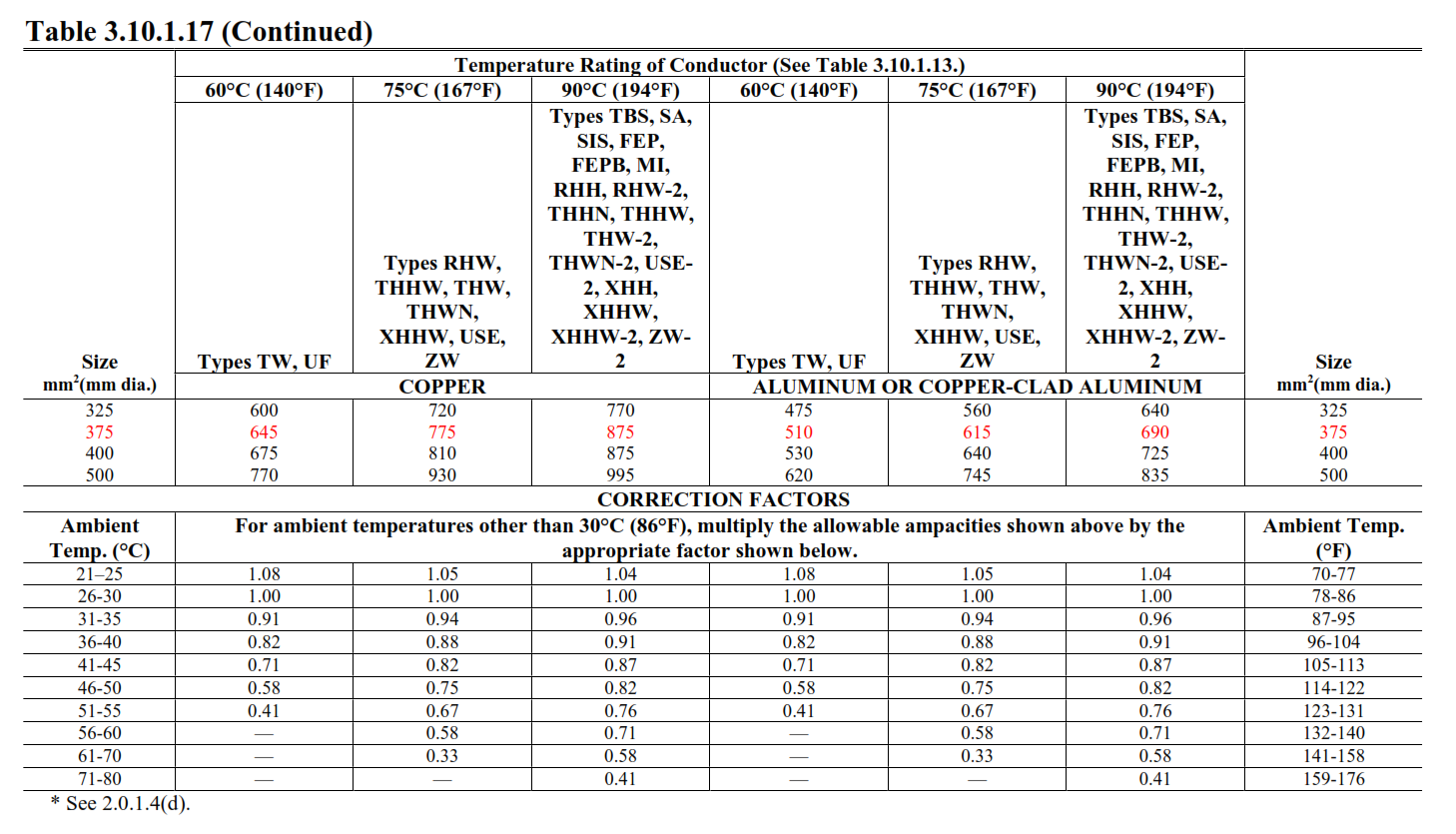

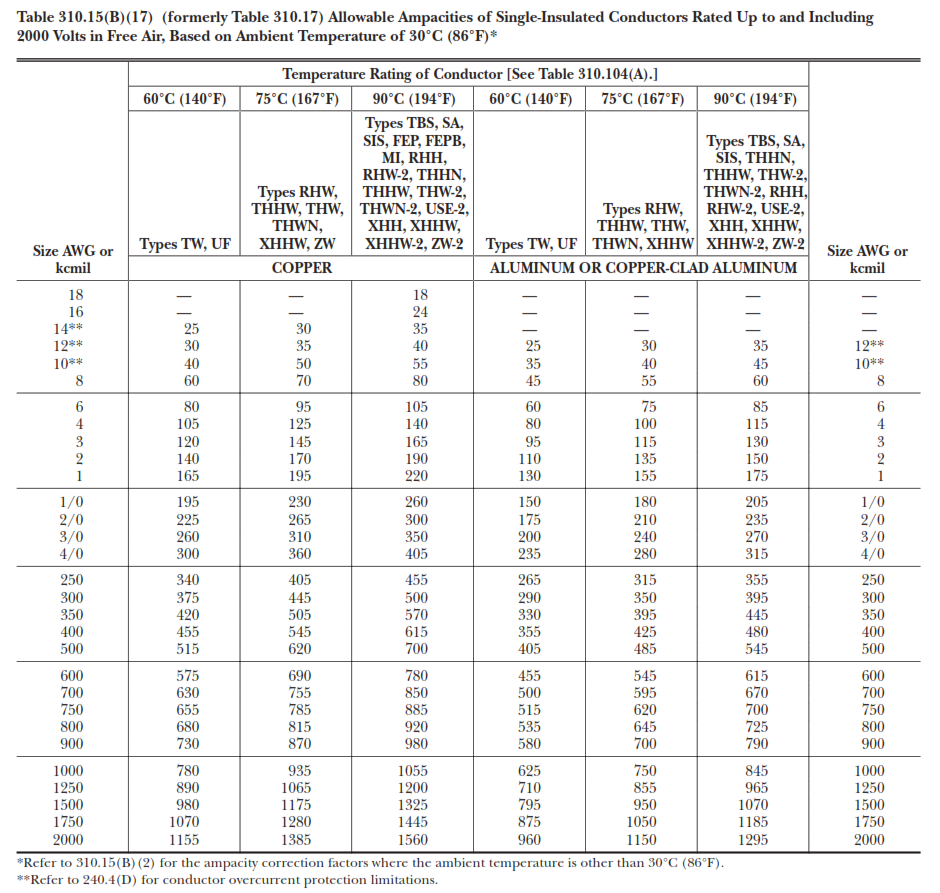

Mostly used reference standard for ampacity of Low Voltage Wires is in Free Air. Philippine Electrical Code (PEC) listed metric sizes in mm^2 referencing from National Electrical Code (NEC), which listed AWG wire sizes.

PEC Table 3.10.1.17

NEC Table 310.15(B)(17)

Note

- Electrical wires generate more heat the larger the current passing through them. That is why the ambient temperature is a major factor in determining the wire ampacity. The higher the ambient temperature is, the lower the ampacity of wires at a given size.

- It is also recommended to refer to manufacturer’s wire ampacity when it is available.

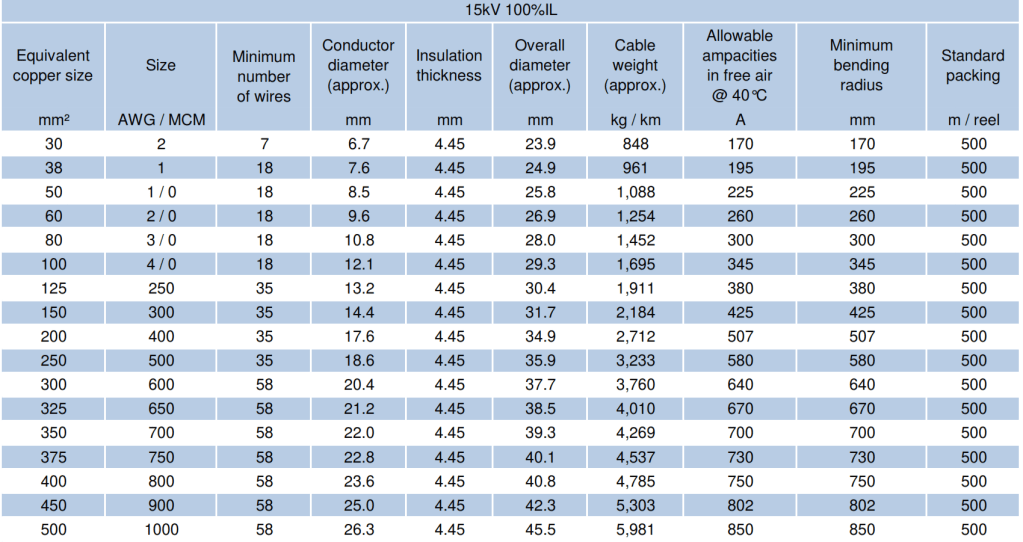

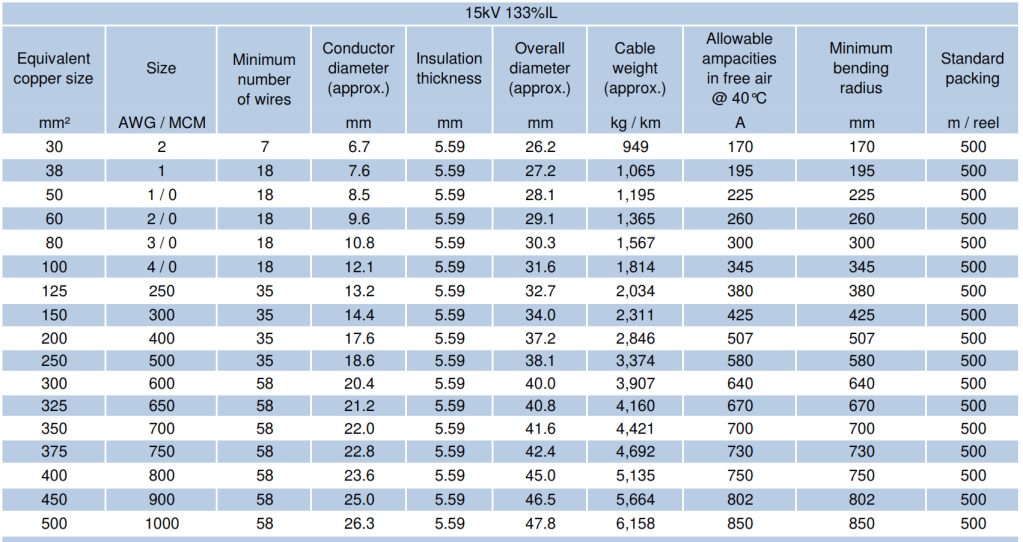

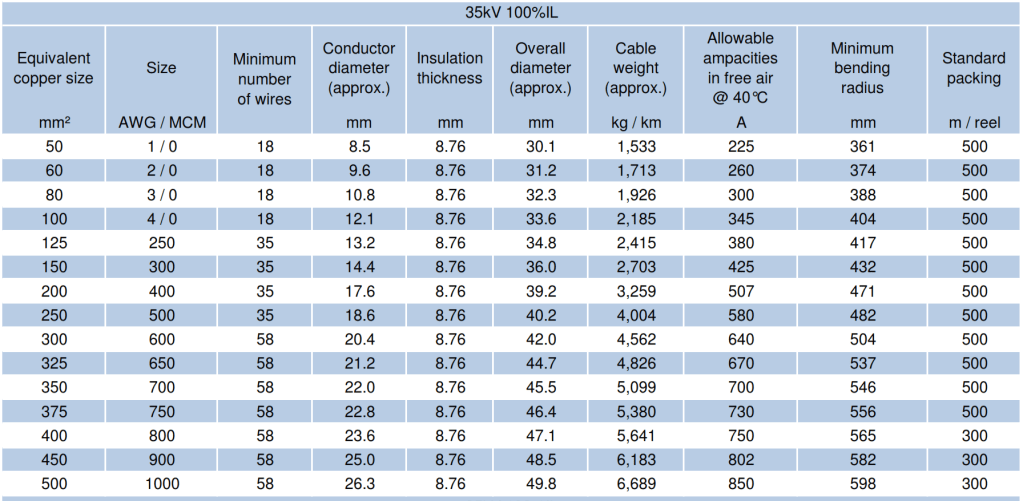

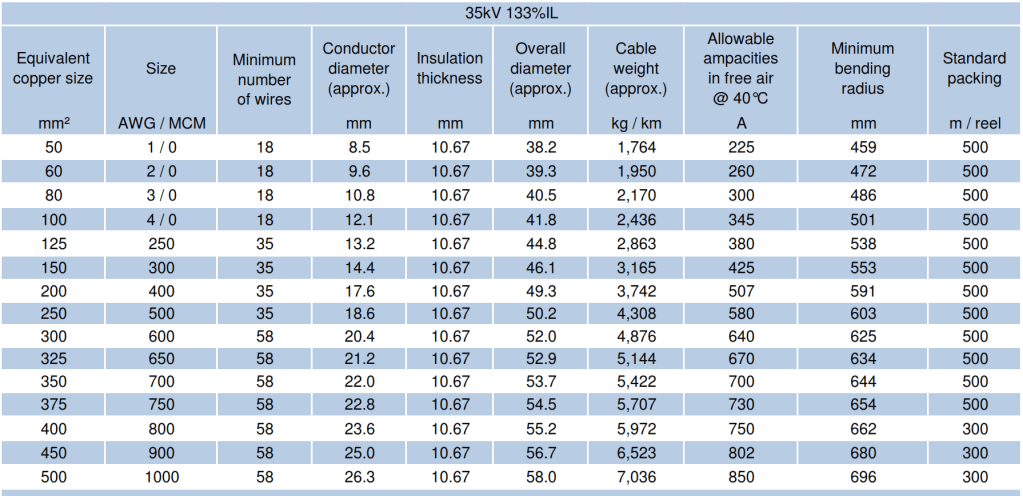

Wire Ampacity Table from Manufacturer (Phelps Dodge)

XLPE Insulation Level, 100% vs. 133%

- 100% = Cables in this category may be applied where the system is provided with relay protection such that ground faults will be cleared as rapidly as possible, but in any case within 1 minute

- 133% = This insulation level corresponds to that formerly designated for underground systems. Cables in this category may be applied where the clearing time requirements of the 100 percent level category cannot be met, and yet there is adequate assurance that the faulted section will be de-energized in a time not exceeding 1 hour.

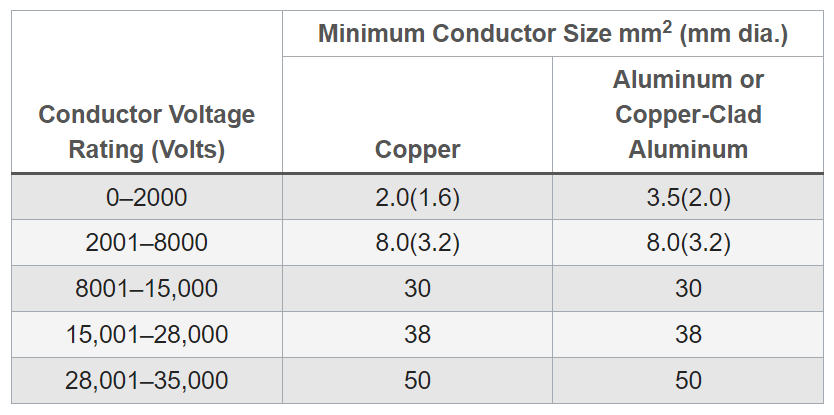

Minimum Size of Conductor

test

LikeLike